Author: Site Editor Publish Time: 2023-09-21 Origin: Site

QUICK COMPARISON:

Laser engraving is the process in which a narrow beam of light is used as a vaporizer chisel, removing thin layers of a material’s surface to engrave text or artwork. More specifically, grooves are carved into a material to replicate the desired image. Laser marking is a broader method of marking objects by changing the color of surface material through melting, charring, or changing the chemical structure, which creates an image. It's the ultimate showdown; fiber laser vs co2 laser. These two post-processing methods have several advantages over other forms of engraving and marking. For example, alternate methods of engraving or marking objects typically involve ink or drilling, which require costly replacement parts and maintenance and complex user interfaces run by skilled technicians. Using lasers to accomplish these tasks is far more cost-effective, capable, and user friendly. Although many laser devices are available for purchase, two main engraver categories exist: the CO2 Laser Engraver and the Fiber Laser Marker. In this article, I will cover the advantages and many uses for each machine.

WHAT IS A CO2 LASER ENGRAVER?

CO2 lasers function by running an electrical current through glass tubes filled with carbon dioxide. As the light bounces back and forth within the tubes, its intensity builds like an echo in a narrow cavern. One end of the tube allows small amounts of light to pass through, exiting the tube to reflect off multiple mirrors eventually aimed at your chosen product. This light’s wavelength is typically in the infrared range, which means that it is not visible to humans. Like energy-efficient infrared cooking ovens, infrared laser light creates a molecular reaction to heat objects with concentrated power. If this light is focused onto a very small point large amounts of heat can be transferred into a material with enough intensity to vaporize its surface layers with smooth precision.

ADVANTAGES OF CO2 LASER ENGRAVING

CO2 laser engraving has the following advantages to consider:

Contact Free Process:

Unlike printers or drills, CO2 laser engravers do not require any contact with the material they are working on. This means that the material is protected and that your engraver requires very little maintenance.

Energy Efficient:

Compared to processes involving drills, the power consumption of a laser engraver is quite low. This means eco-friendlier and more cost-effective production.

Safety Driven:

Most CO2 laser engravers are contained in a protective case and thus minimize the risk of an accident.

Versatile with Applications:

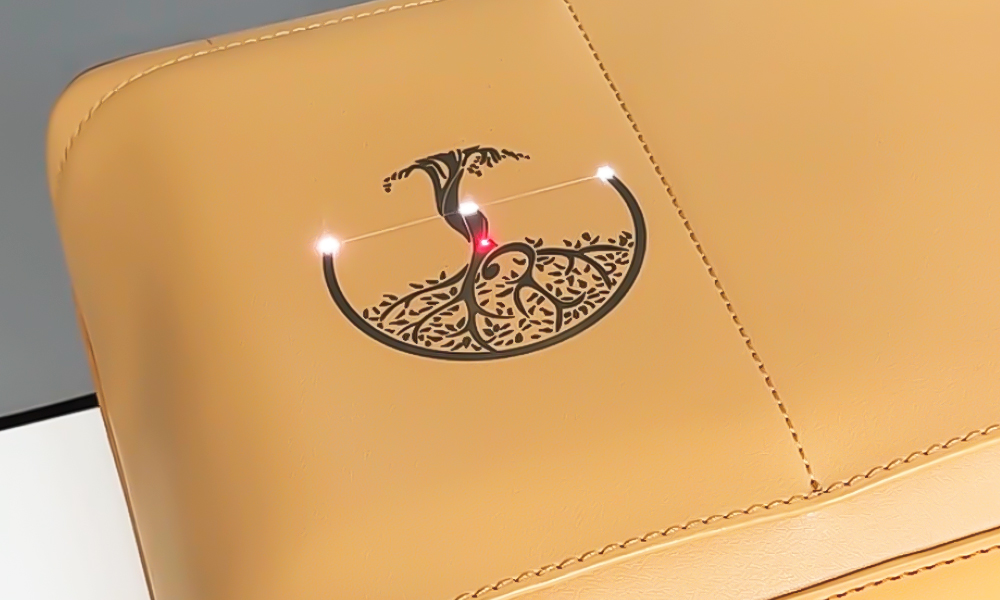

Several materials can be engraved with messages or artwork using a laser engraver. These materials include glass, plastic, leather, wood, and more.

Compact Size:

CO2 laser engravers do not require large facilities to own and operate. In fact, some of our models are desktop sized.

USES OF A CO2 LASER ENGRAVER

A CO2 laser engraver is perfect for hobbyists and small business owners due to their affordability and ease of use. This machine is also the perfect choice for small-scale arts and crafts projects. A few craft ideas include laser engraved keychains, custom craft beer pint glasses, engraved wooden souvenir postcards, and laser etched photo crystal gifts. This versatility and ease of use make this device ideal for beginners, let alone all levels of users

WHAT IS A FIBER LASER MARKER?

A fiber laser marker works on a similar principle as a CO2 laser engraver. However, a key difference is that an optical fiber coated in rare earth elements is used in a fiber laser vs CO2. The fiber laser concentrates light into a narrower point, resulting in a higher intensity beam that can transfer more energy into the desired material. Therefore, fiber laser markers are used for more industrial surfaces such as metals and hard plastics.

ADVANTAGES OF FIBER LASER MARKING

Fiber Laser Marking has the following advantages to consider:

Low Maintenance Costs:

Few moving parts mean that maintenance requirements are low sparing the user cost and worry.

Highly Energy- Efficient:

Fiber lasers efficiently deliver energy to the material they are marking. This means lower energy costs and a more environmentally friendly production process.

Precise and High Contrast Marks:

Marks created with this device are precise and have high visibility due to sharp contrast with the material being marked.

No Surface Damage:

Fiber Laser Markers only mark the very top layer of a material without impacting the surrounding areas - maintaining greater material integrity.

Ability to Mark Metals and Hard Plastics:

Fiber Laser Markers can be used on a wide variety of metals and hard plastics. Although CO2 laser engravers can be used on these materials as well, they require a thermal/laser bond spray and multiple passes to achieve the desired results.

USES OF A FIBER LASER MARKER

The applications of a fiber laser marker are slightly different than those of a CO2 laser engraver and tend to be more specialized and professional in nature. Fiber laser marking only affects the very surface layer of material without impacting the surrounding area. This is particularly important where the material might be easily damaged or needs to preserve its mechanical properties (e.g. computer chips and structural components). This device can create a custom image or message on silverware, knives, watches, and other metal objects making it useful for more serious hobbyists. Although fiber laser markers can be helpful for hobbyist-like projects, small business purposes may be more suitable. A small business owner who manufactures small to medium-sized batches of metal or hard plastic products will need a quick and affordable way to serialize them. This will require high contrast and durable serial numbers, bar codes, or QR codes. A Fiber Laser Marker can provide this with high energy efficiency, quick turnaround time, and low maintenance.

Industrial Park Weiji Town, Xuzhou City,Jiangsu Province,China

Industrial Park Weiji Town, Xuzhou City,Jiangsu Province,China +86 551 62630332

+86 551 62630332 info@vanklaser.com

info@vanklaser.com  +86-153-1885-9065

+86-153-1885-9065